What is Injection Molding?

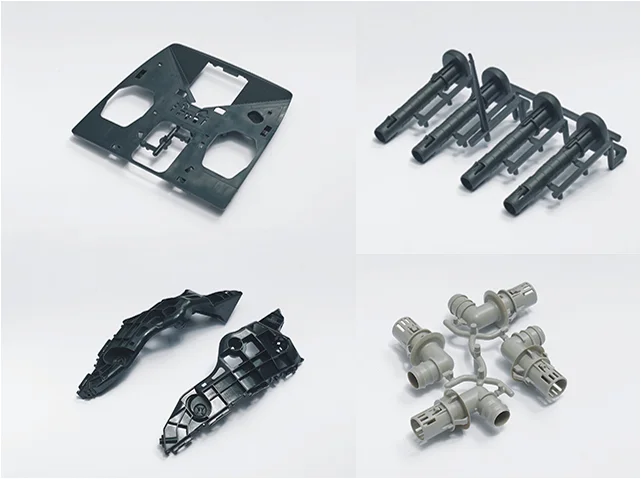

Injection molding is a plastic molding technique and the most cost-efficient approach for large-scale manufacturing of plastic components. The process of injection molding involves melting the thermoplastic into a liquid state, followed by high-pressure injection into a two-sided mold. After cooling and solidification, the part of a specific shape pops out.

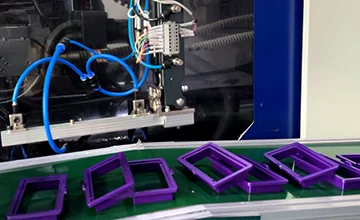

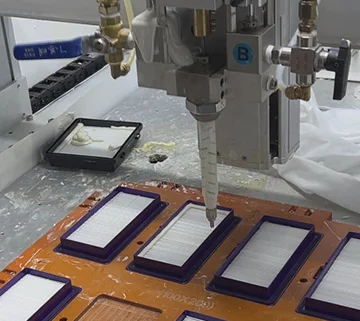

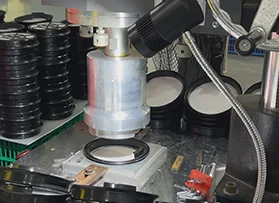

Since 2004, Sanken has entered the domain of injection molding. After over 20 years of precipitation and accumulation, we now have professional technicians and production workers, as well as a variety of injection molding machines of different models. We also possess two-color injection molding machine, specializing in filter injection molding and assembly processing services for various vacuum cleaner manufacturers.

english

english