| Ⅰ | Thermoformed Lightweight Auto Components | Sanken is committed to the research and development of comfortable, environmentally friendly, lightweight auto parts products, with 400 tons of hot press equipment, we can process products within 2.5m * 1.2m. currently produce and supply hood sound insulation pads, outer front wall sound insulation pads, battery heat shields, bottom guards, hub covers, trunk cover trim, trunk side trim panels, spare tire covers, inner front wall sound insulation pads, motor covers and other new energy vehicle accessories. |

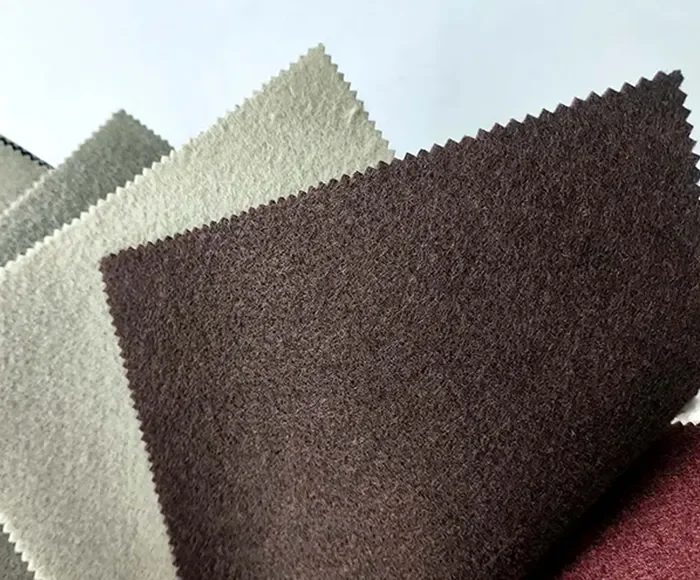

| Ⅱ | Foam/felt soundproofing padding components | Foam/felt is often used in the automotive field for interior filling to play the role of sound insulation, heat insulation, etc. Sanken focuses on providing high-quality and stable foam/felt and other sound insulation products for automobile manufacturing customers, and provides different felt formulas according to different customer needs, so as to effectively save costs for customers while ensuring quality. |

| Ⅲ | Double-Sided Tape/Skin Gluing Processing | Double-sided tape die-cutting and skin gluing process is widely used in the automobile manufacturing industry, Sanken precision cutting machines provide die-cut double-sided tapes for car badges, and also supply badge backing plates, making car badge installation more convenient and ensuring better adhesion. Dermal gluing ensures tight and stable bonding while making the installation process more convenient and fast. |

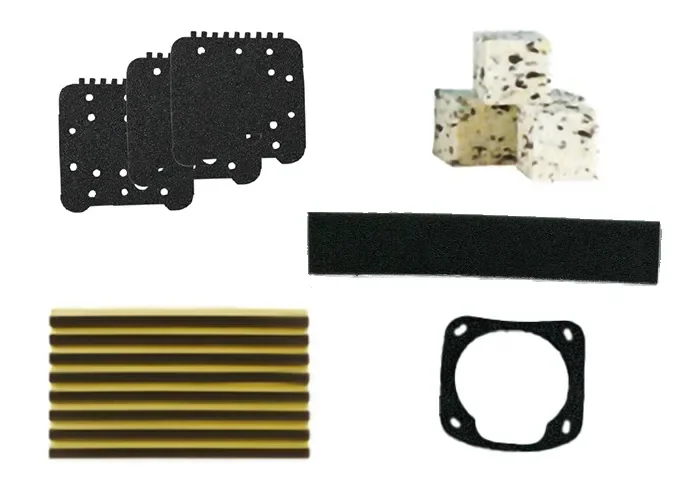

| Ⅳ | Sponge Foam Blocks/Circles/Padding Components | Our precision die-cutting machine can provide you with any shape of sponge foam accessories components, our sponge blocks, sponge rings, sponge pads and other components are often widely used in air conditioning systems, serving as filters, buffers, shock absorbers, and sealants. |

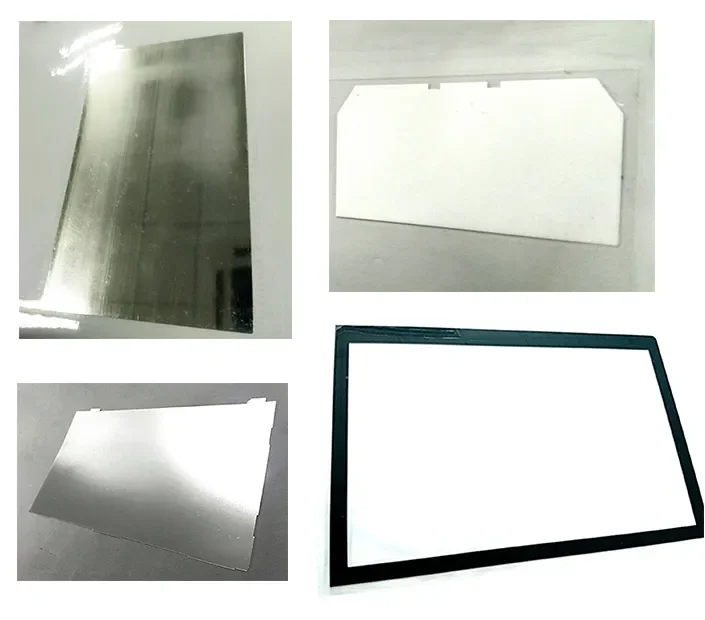

| Ⅴ | Screen Films/Shading Tapes For Automotive Display Modules | In today's highly innovative and intelligent world, smart display has become an indispensable functional component in automobile manufacturing. Sanken dust-free workshop and high-precision die-cutting equipment meet the processing requirements of the majority of automobile manufacturers and display module manufacturers, and can customize and process a variety of series accessories such as screen display lenses, screen protection films, screen shading tapes, etc. |

| Ⅵ | Plastic/Rubber Products | Sanken focuses on injection molding and rubber molding solutions, providing plastic injection parts like bumper for automobiles, and also supporting custom processing of various rubber pads and rubber strips to buffer or seal in your automobiles. |

| Ⅶ | Labels | Labels are widely used in all walks of life, and in the automotive industry, labels are also used for product information, certificates, safety warnings, etc. We provide general printing and screen printing services, supplying high-definition, high-tear resistance, high water resistance and other special requirements such as reflective function to automotive manufacturers, suitable for different positions and environments. |