| Ⅰ | Foams | Foams are widely used in various industries, and in the field of 3C electronics, various foams are often customized into different shapes to be used to prevent vibration and fall, seal and assist in fixing. Sanken provides adhesive lamination and precision die-cutting services, which can customize different specifications and shapes according to your needs, and can also provide adhesive backing according to your needs to save your product assembly time. |

| Ⅱ | Adhesive Tapes | Tape accessories are widely used in the 3C field and usually play a fixed role. According to different tape properties, the common ones are double-sided tape for fixing, insulating tape for insulation, copper foil and aluminum foil tape for shielding, heat dissipation tape for heat dissipation, and so on. Your needs are in Sanken, and we will do our best to meet them. |

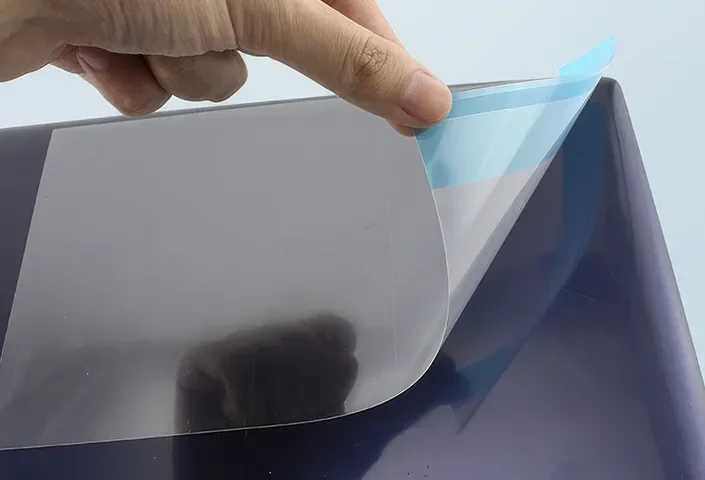

| Ⅲ | Films | From the most common protective films to the insulating diaphragms inside, films are extremely versatile in 3C electronics. Sanken can customize and supply screen protectors, lens protectors, internal insulating sheets and other die-cutting parts related to films. |

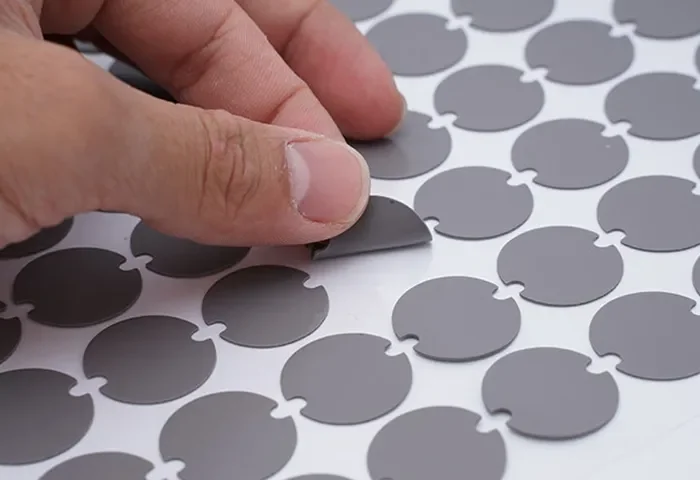

| Ⅳ | Silicone Grease, Graphite Heat Dissipation | In 3C electronics, heat dissipation is very important. At this stage, the heat dissipation of mobile phones, routers, etc. is usually pasted with heat dissipation silicone grease sheets, graphite gaskets or other gaskets with thermal conductivity properties. |

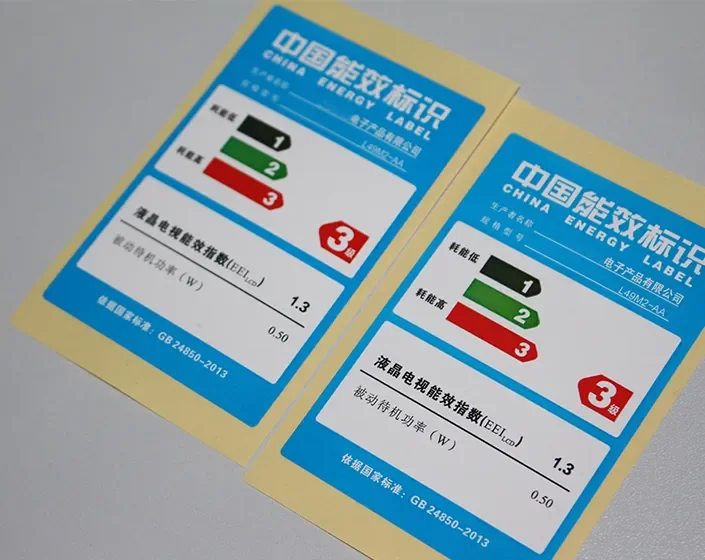

| Ⅴ | Labels and Silk Screens Printing | 3C electronic products generally have product name labels, 3C certification labels, and special body logos or instructions, which generally use label printing or screen printing technology. Sanken has advanced printing equipment and experienced workers, specializing in providing you with printing and screen printing customization services. |

| Ⅵ | Rubber | Rubber accessories are mainly used for sealing cushioning or anti-slip, and rubber gaskets, gaskets, and some anti-slip patches are used in 3C electronic products. Sanken's rubber molding workshop and die-cutting workshop specialize in providing all kinds of rubber molding processing. |

| Ⅶ | Plastics | In the field of shells for 3C electronics, it is mainly plastic or metal shells. Sanken has mold precision machining, injection molding, and hot pressing technology, which can be customized for you to inject or heat press your plastic accessories, such as back covers, etc. |

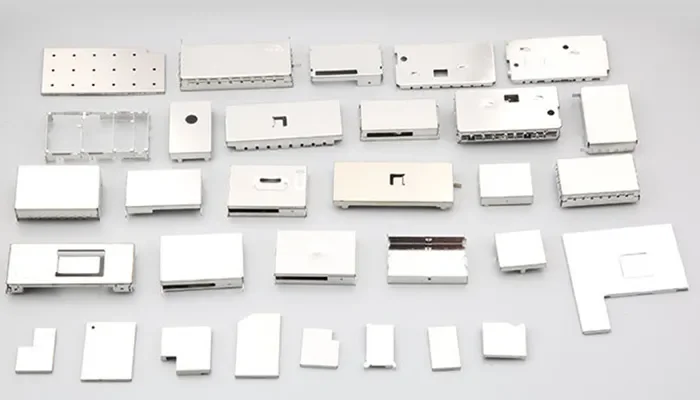

| Ⅷ | Metals | Metal accessories will be found both outside and inside 3C electronic products, such as metal shells, shielding covers, etc. |

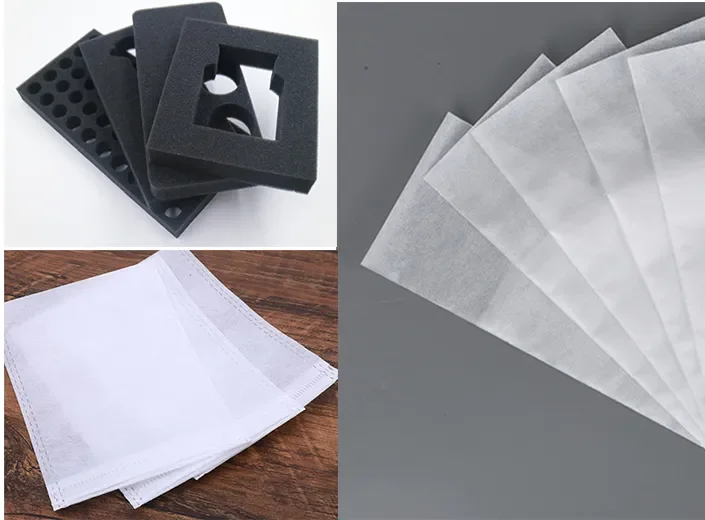

| Ⅸ | Packaging and Other Components | According to their performance and price, the packaging of 3C products is also different, some products need to use sponge frames, some products will use non-woven protective bags, etc. Sanken's non-woven processing and die-cutting processing can meet your customized needs for sponge cutting and non-woven protective bags. |